Image 1 of 4

Image 1 of 4

Image 2 of 4

Image 2 of 4

Image 3 of 4

Image 3 of 4

Image 4 of 4

Image 4 of 4

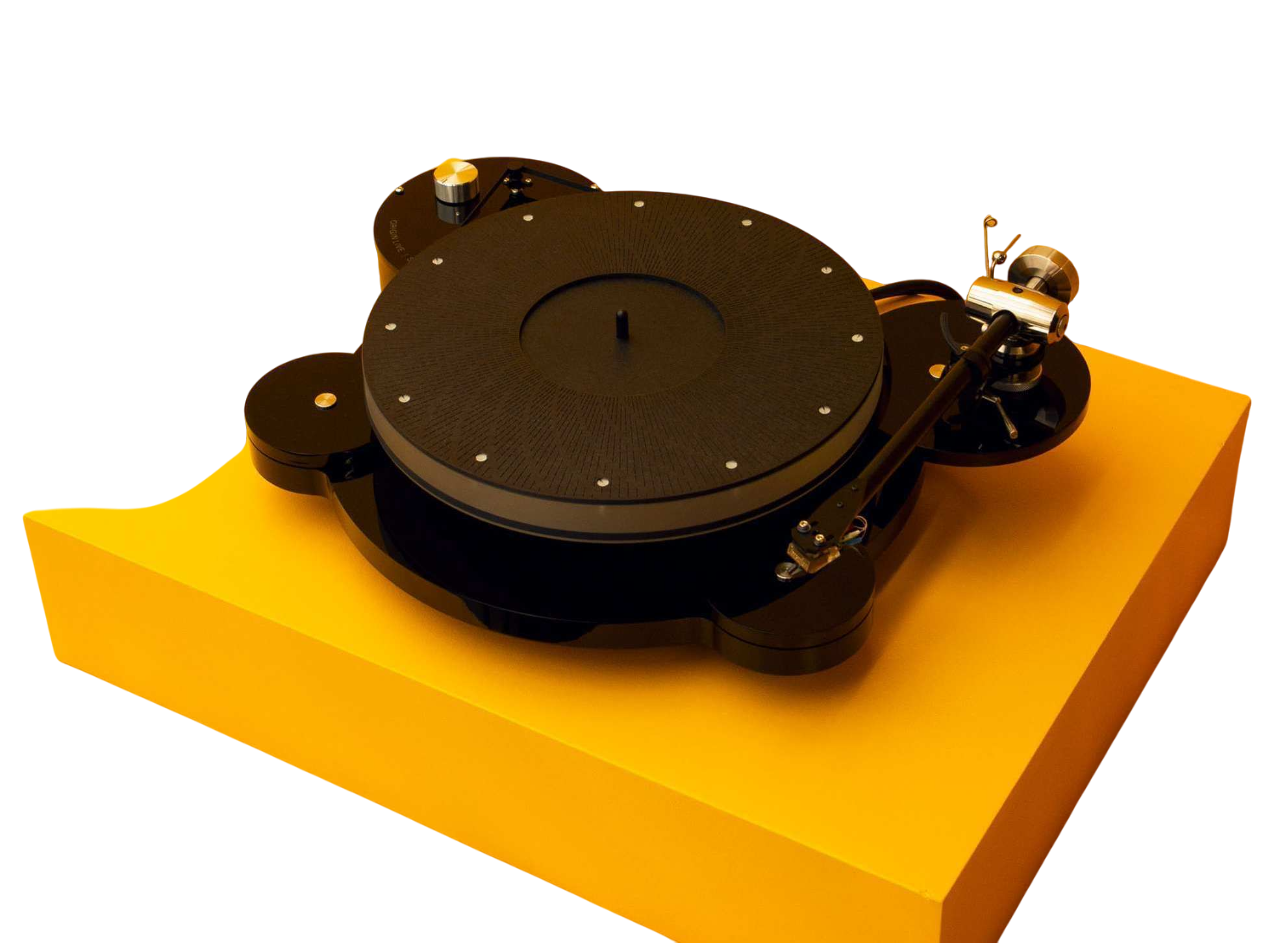

Kuzma XL AIR Turntable

The XL AIR turntable differs from the Stabi XL DC turntable by using an air bearing and an additional bronze platter, resulting in a total platter mass of 44 kg. The Stabi XL DC can be upgraded to the XL AIR version by installing the XL AIR kit. Current delivery time is 30–45 days.

The XL AIR turntable differs from the Stabi XL DC turntable by using an air bearing and an additional bronze platter, resulting in a total platter mass of 44 kg. The Stabi XL DC can be upgraded to the XL AIR version by installing the XL AIR kit. Current delivery time is 30–45 days.

The XL Air turntable uses an air bearing instead of a conventional bearing, improving two key parameters in turntable design. First, air bearings have virtually zero friction, resulting in no self-generated vibrations in the bearing itself and therefore eliminating noise reaching the cartridge. The second advantage—when the air bearing is properly engineered (not merely floating on an air cushion)—is its ability to support a higher load.

The total mass of the rotating platter is 44 kg, making it more resistant to the slowing effects of cartridge drag, which affects all platters regardless of mass or drive type. The top platter—identical to that of the XL DC turntable (22 kg)—is a sandwich construction of aluminum and acrylic plates, screwed together in a pre-stressed form to dampen unwanted vibrations. The lower platter (22 kg) is made of cast bronze, which also offers excellent damping properties.

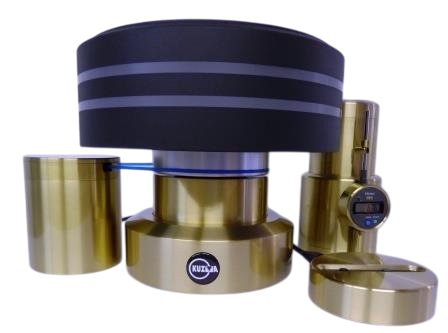

The air bearing operates using compressed air supplied by an external air source. This air supply consists of a compressor and air filters. (For more details, see the relevant section of this manual.) The turntable’s air bearing consists of two bearing surfaces: the top surface carries the vertical load, while the cylindrical bore handles the horizontal load. The air bearing features a 31 mm shaft and a 60 mm thrust plate. Its surfaces are made from porous carbon, containing millions of microscopic pores that release pressurized air. This design ensures more uniform pressure within the 5-micron bearing gap at 4 bar, resulting in a stiffer bearing with no play.

The base supporting the air bearing is made from two solid brass components, clamped together, providing excellent damping characteristics.

-

Mass (total w/o PS and compressor): 120 kg

Platter aluminium- top: 22 kg

Bronze platter- lower: 22 kg

Base: 27 kg

Motor tower: 7,5 kg

Tonearm tower: 14 kg ( No. 1)

Air pressure: 4 bars

Speeds: 33, 45, 78 rpm

Dimension- turntable: 450x 400 x 300 mm

Dimension-compressor: 180x410x430 mm

Compressor mass: 20 kg - See NOTE above ( XL AIR compressor-model 50D can NOT also supply air for Air Line tonearm)

Power supply: 110V or 240 V, 50/60Hz (factory set)

Finish: standard laquered brass or RAL mat colours

-